Compatible: (2.7L/3.5L/5.7L/6.1L)

2008 - 2010 Dodge Challenger

2006 - 2010 Dodge Charger

WILL FUNCTION WITH ELECTRONIC DAMPER CONTROL DISABLED

- 02: Front height adjustable by threaded shock bodies. Rear height adjustable by adjustable spring perch.

- 97: Front Clubsport top mounts included.

- X11: 2-way adjustable Clubsport Kit

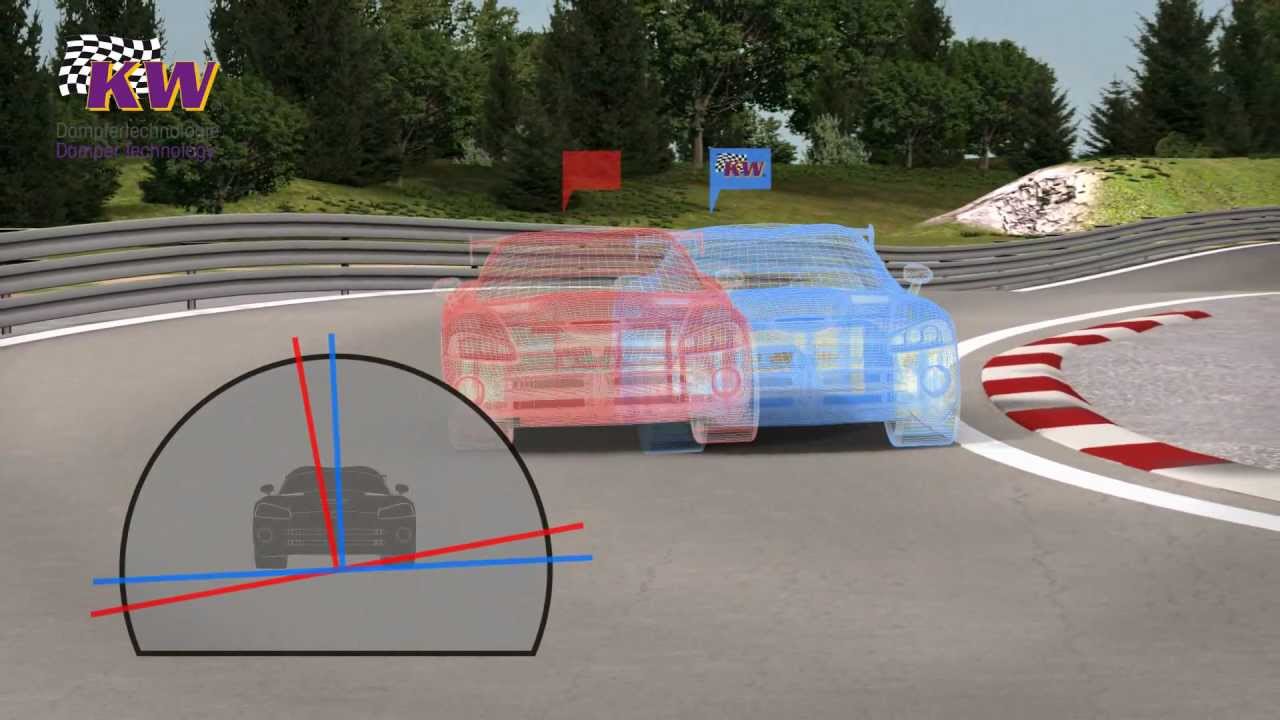

These set ups were specifically designed for the Nordschleife using track day tires. By using the optional adjustable top mounts, suspension geometry can be adjusted to the requirements of the tires and the intended use.

These adjustable top mounts coupled with the independently adjustable rebound and compression dampening technology individual set up adjustments according to vehicle load, tire characteristics and different track conditions. Clubsports meets all needs for the road and the race track guaranteeing excellent handling, best performance, great agility and fantastic lap times.

The rebound adjuster knob provides 16 precise clicks to personally dial in your desired vehicle setup. Thus allowing you the possibility to influence wheel/tire loads or take into concern chassis characteristics. Independent from rebound adjustment is the compression dampening, 12 precise adjustment clicks are provided to adjust the low-speed dampening. Most notably used to dial in wheel/tire setup.

These adjustment features allow the user to dial in vehicle weight, wheel/tire combinations, various road surfaces and environmental conditions.

- Independently adjustable rebound and compression damping technology

- Stainless steel technology "inox-line"

- Continuous lowering

- TÜV-tested adjustment range

- High-quality components for a long-term durability

- Adjustable rebound damping with 16 precise clicks

- Adjustable compression damping with 12 precise clicks

- Unique independent damping force adjustment

- Optional spherical bearing aluminum top mounts

KW Damping and Valve Technology, 2-Way

KW's adjustable damping technology is offered for a wide selection of applications and vehicle categories.

Damper Basics - The Function of a Shock Absorber

The primary job of a shock absorber is to subside vibrations caused by the wheels, axles, and body. The technically correct name for it would be a vibration damper. When driving over irregularities, the force generated or vibrations that are created should be absorbed by the suspension. A proper working damper should prevent the following:

- Excessive body motion or roll during bumps or irregularities

- Nose lifting and diving during acceleration or braking

- Wheel bouncing or losing contact with the ground

- Loss of stability or traction during braking

- Loss of control in turns because of low traction

The shock absorbers used in vehicles are usually twin-tube dampers or mono-tube dampers. A piston moves in an oil-filled cylinder in both damper types. The piston forces the oil through the valves, which creates resistance to the oil flow with the help of various holes and orifices.

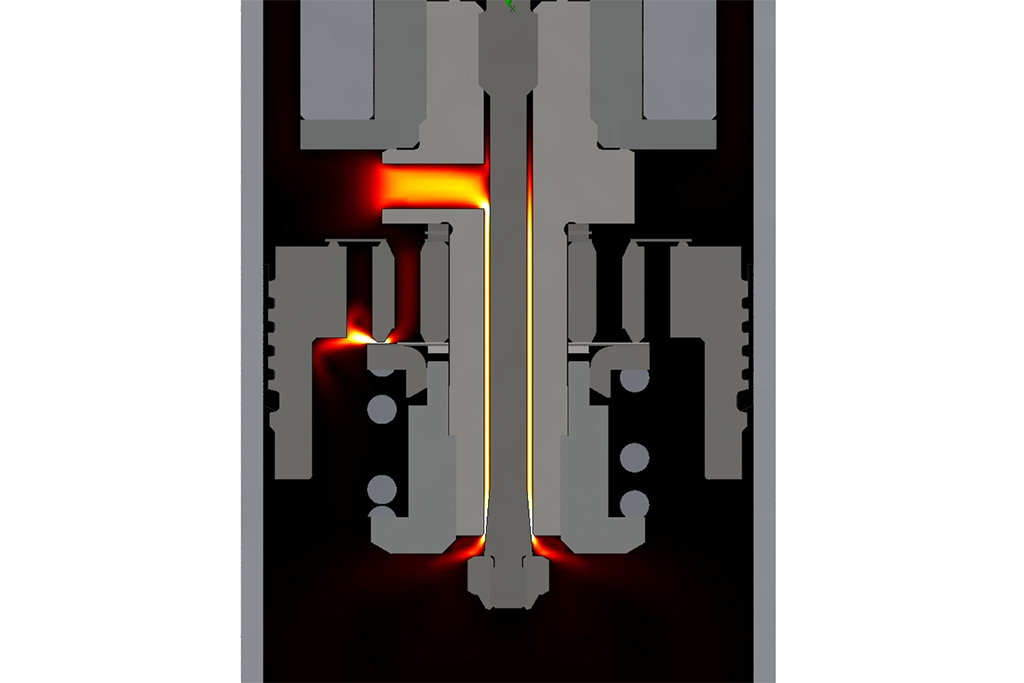

During rebound, the oil flows from the outer tube back into the inner tube. In addition to the channels in the bottom valve, the oil also has to flow through the rebound valve located at the piston rod, to get into the piston housing.

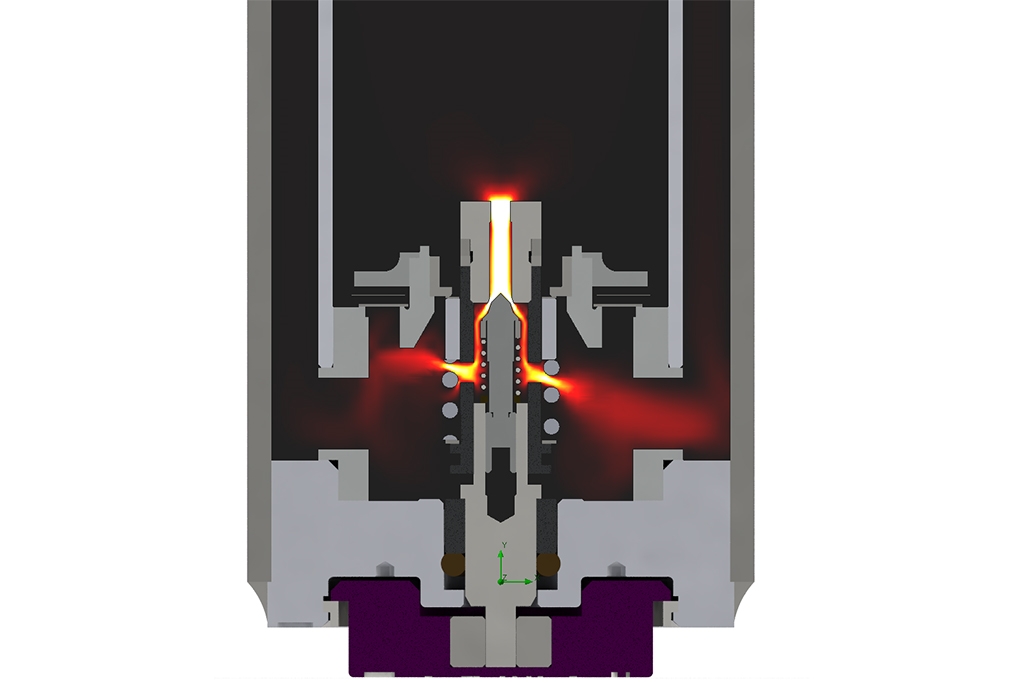

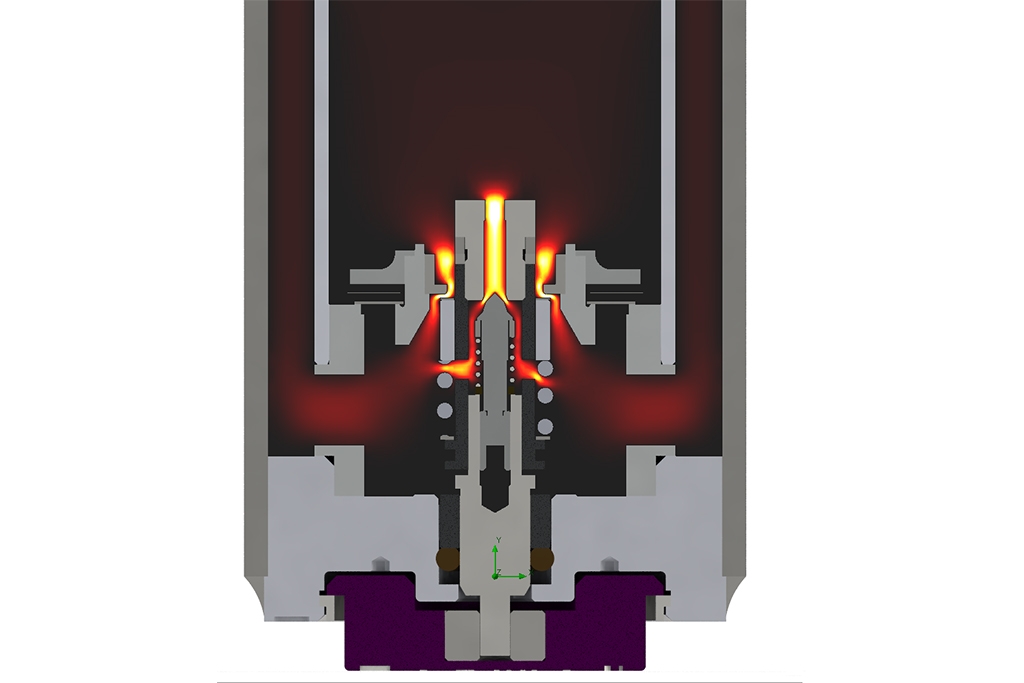

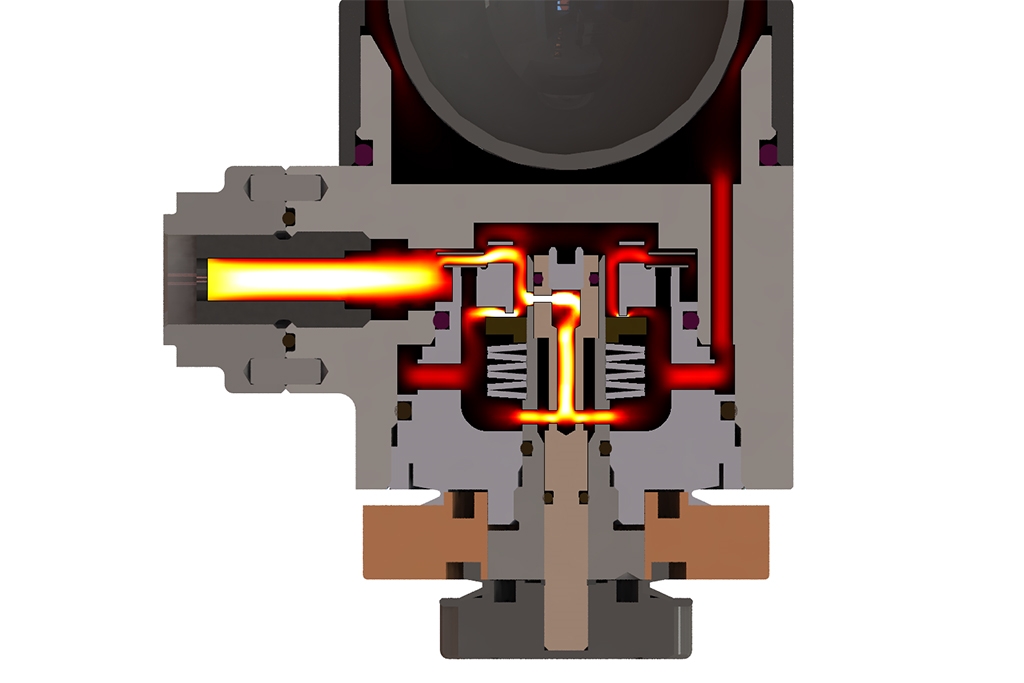

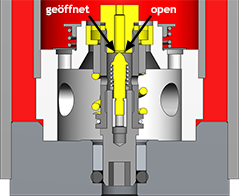

How a KW Twin-Tube Shock Absorber Functions

When the cars damper reacts while driving, the oil, which is under minimal pressure, will be displaced by the immersion of the piston rod. The oil then flows into the outer tube through the bottom valve (compression valve) which controls the flow speed. During rebound, the oil flows from the outer tube back into the inner tube. In addition to the channels in the bottom valve, the oil also has to flow through the rebound valve assembly located on the piston rod.

The spring has to absorb and release the stored energy. In a short sequence of these repetitive disruptions, a vibration arises. These movements are transmitted via the piston rod to the shock absorber. Here the kinetic energy is converted to heat by hydraulic resistance in the shock absorber valve and reduces the vibrations to an inaudible minimum.

Rebound Adjustment

Independently adjustable rebound damping

Rebound adjustment with an allen key

Rebound adjustment with the KW adjustment knob, when space allows

Rebound adjustment with an integrated adjustment dial

16 Clicks - Best Perfomance and easy Adjustment

All KW coilover kits that utilize KW's TVR-A (Twin Valve Rebound - Adjustable) technology which provides 16 clicks of independent rebound adjustment.

Rebound adjustments can be made to reflect more dynamic driving characteristics or complement a change in tire selection like a different set of wheels or winter tires.

The adjustable rebound feature allows the user to dial in a more sportier tighter handling characteristic or a more compliant comfortable setting.

Technical details of adjustable rebound damping

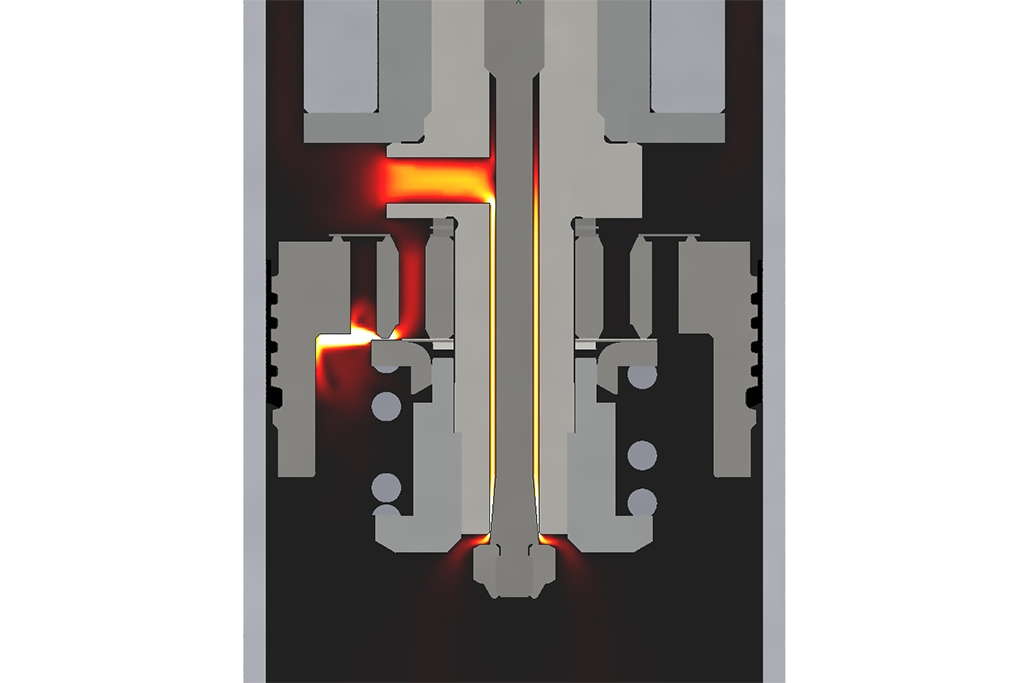

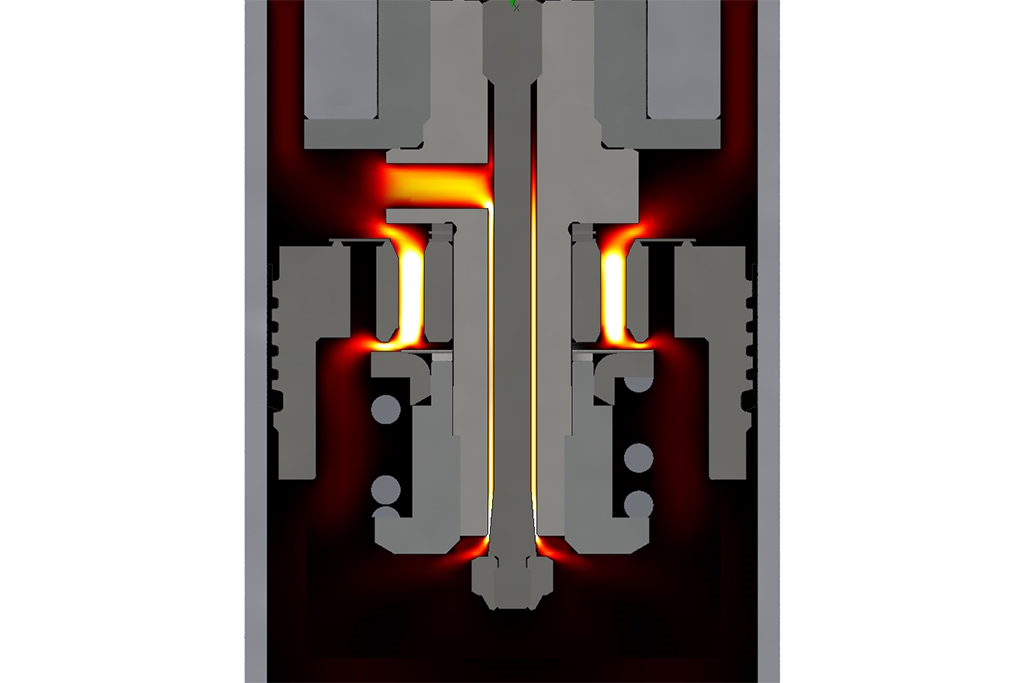

Oil flow during high rebound setting

Bypass orifice with high rebound force position. Digressive damping characteristic and the maximum achievable rebound damping. Damping is determined by the setup specific preload of the valve spring in the piston.

The result:

A firm but not a hard rebound stroke, more resistant to rolling and pitching motions.

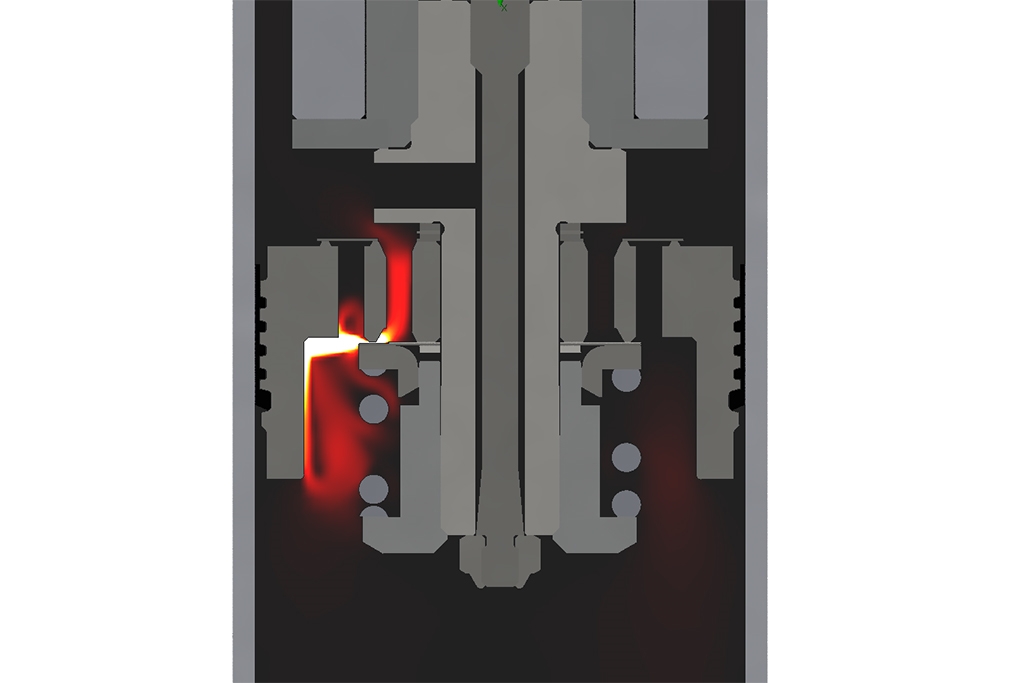

Oil flow during low rebound setting

Bypass orifice with open adjuster position allowing for a progressive damping characteristic and ability to achieve minimum possible rebound damping .The bypass oil volume (black arrows) is reduced for the spring preloaded valve on the piston and the damping forces are therefore reduced.

The result:

A lower rebound damping increases the driving comfort.

Graphic representation of the relation from damper speed (m/s) to damping force (N) when adjusting the rebound damping.

Compression Adjustment

Independently adjustable compression damping

Compression adjustment with an

allen key

Compression with a pin wheel adjuster, accessible through an adjustment window

Compression adjustment by use of a integrated adjustment wheel placed at the bottom of the damper

Compression adjustment by an integrated adjustment wheel

12-way adjustable compression damping with a distinct and tactile click.

The KW Variant 3 and KW 2-Way Clubsport coilovers feature KW's TVC-A (Twin Valve Compression - Adjustable) technology and are the ideal system for performance orientated driving enthusiasts who value an a wide range of damping adjustments for their vehicles.

The independently adjustable rebound and compression damping provides an extensive range of damper tuning. This enables the enthusiast to directly effect the turn-in characteristics, stability, tire grip, and handling at the vehicle's limits.

The patented KW valve technology for independent rebound(TVR-A) and compression (TVC-A) damping allows the user to customize their KW damper setup.

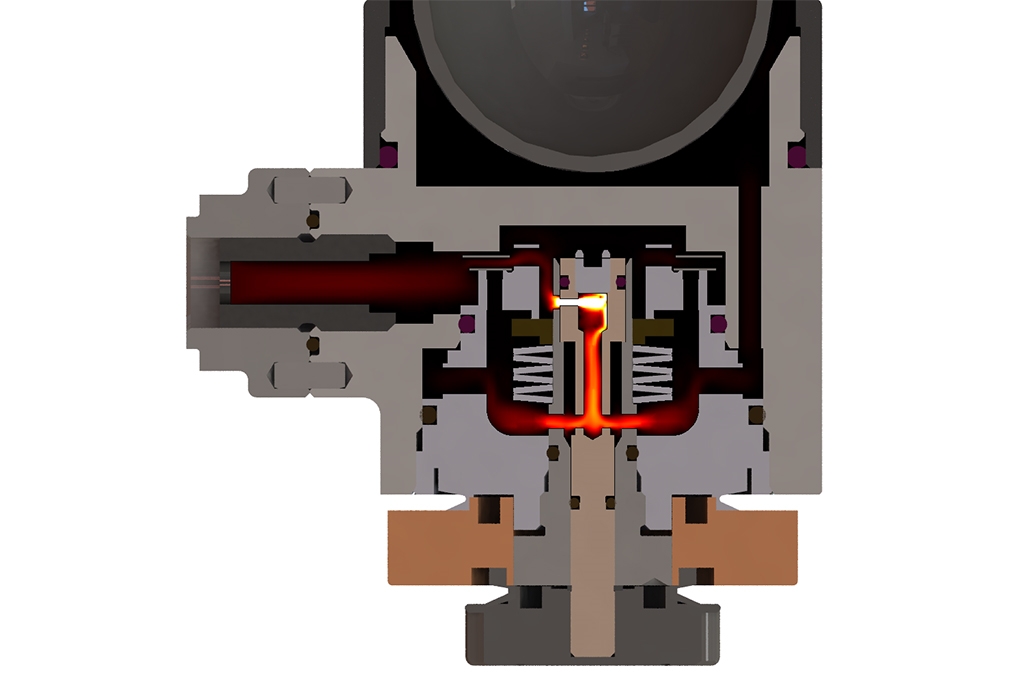

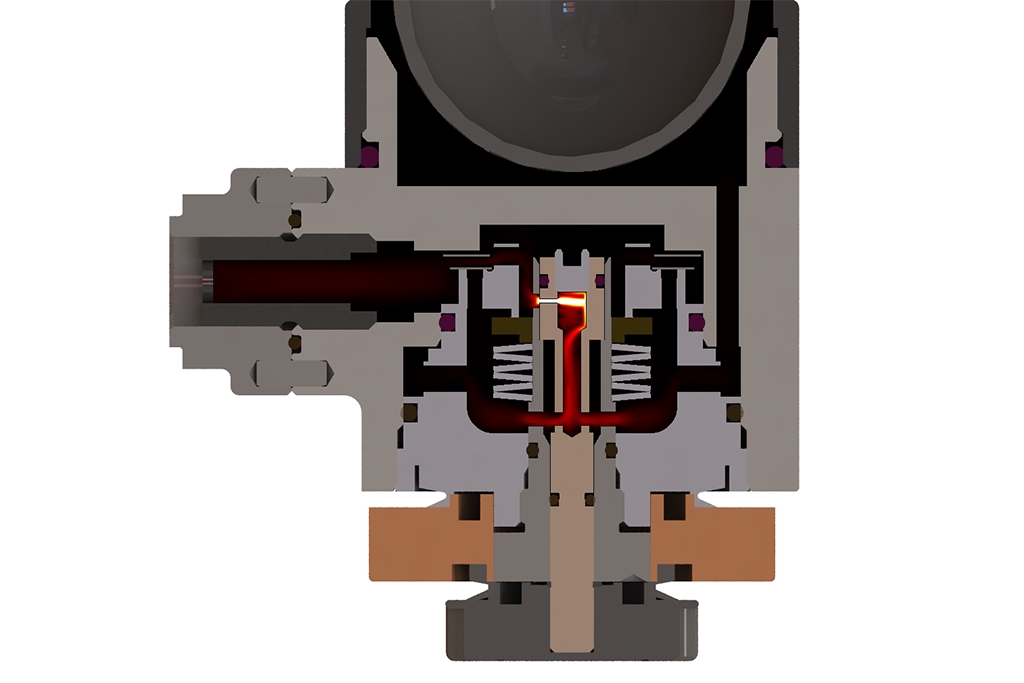

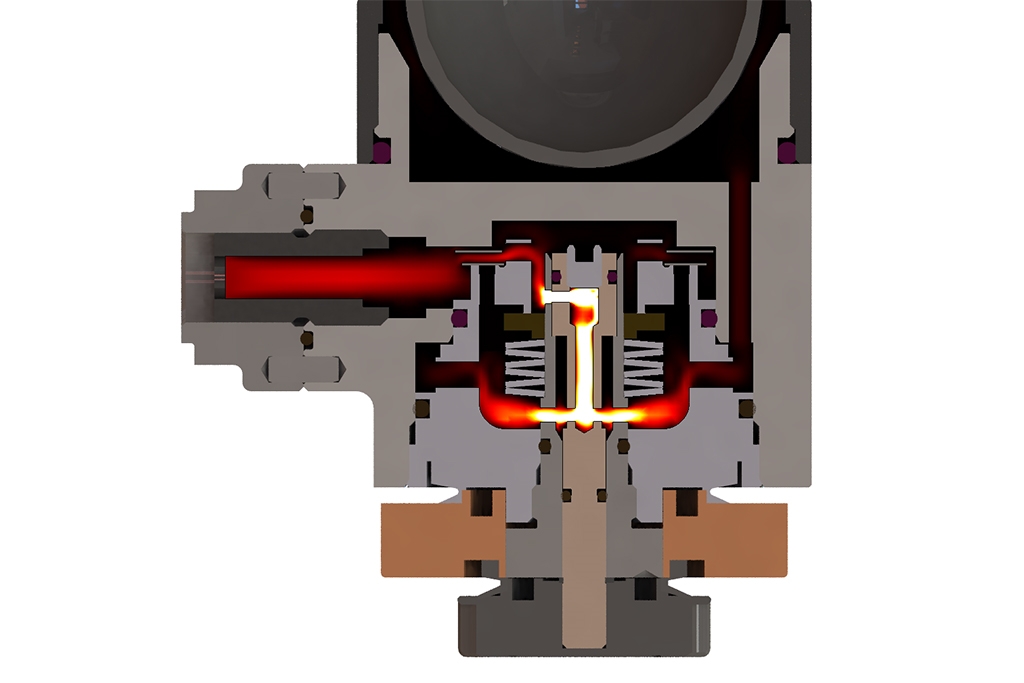

Technology of Compression Damping in Detail

Graphic representation of the relation from damper speed (m/s) to damping force (N) when adjusting the compression damping.

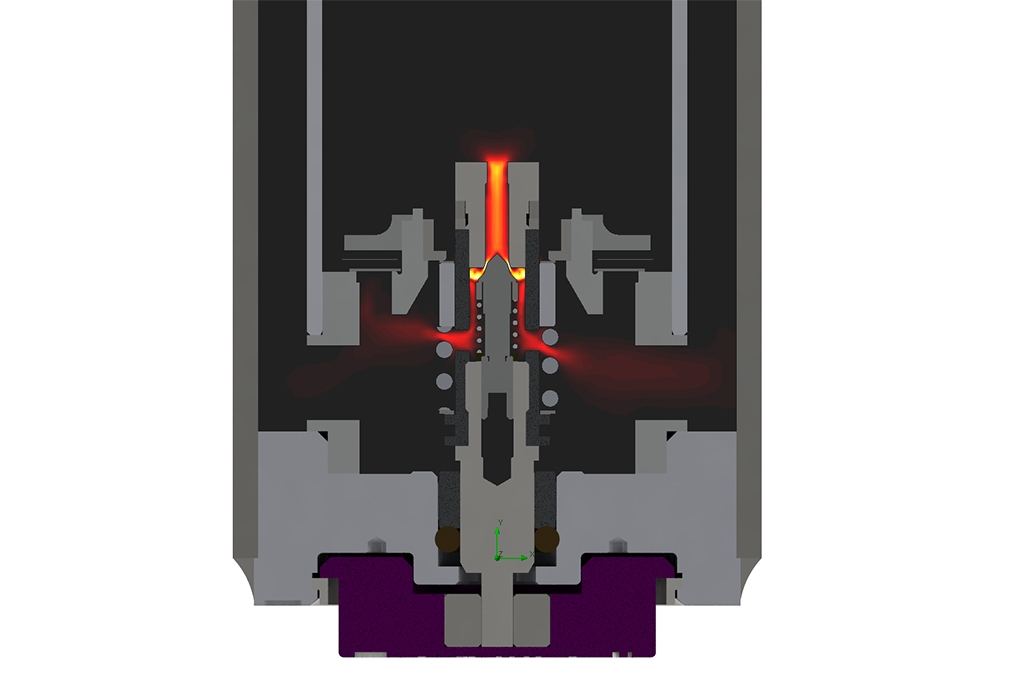

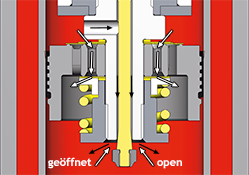

Oil flow during high compression setting

Figure 1:

Spring preloaded needle valve in high compression setting before compression stroke begins

Figure 2:

Position of the needle valve with increasing piston rod velocity

During low piston rod velocity (black arrows), oil is flowing over the spring loaded needle valve

The high speed compression damping (white arrows) is generated by the spring preloaded sleeve. The closed compression valve generates a progressive characteristic low-speed compression damping graph

The result:

A firmer compression stroke adjustment prevents the vehicle from rolling during cornering

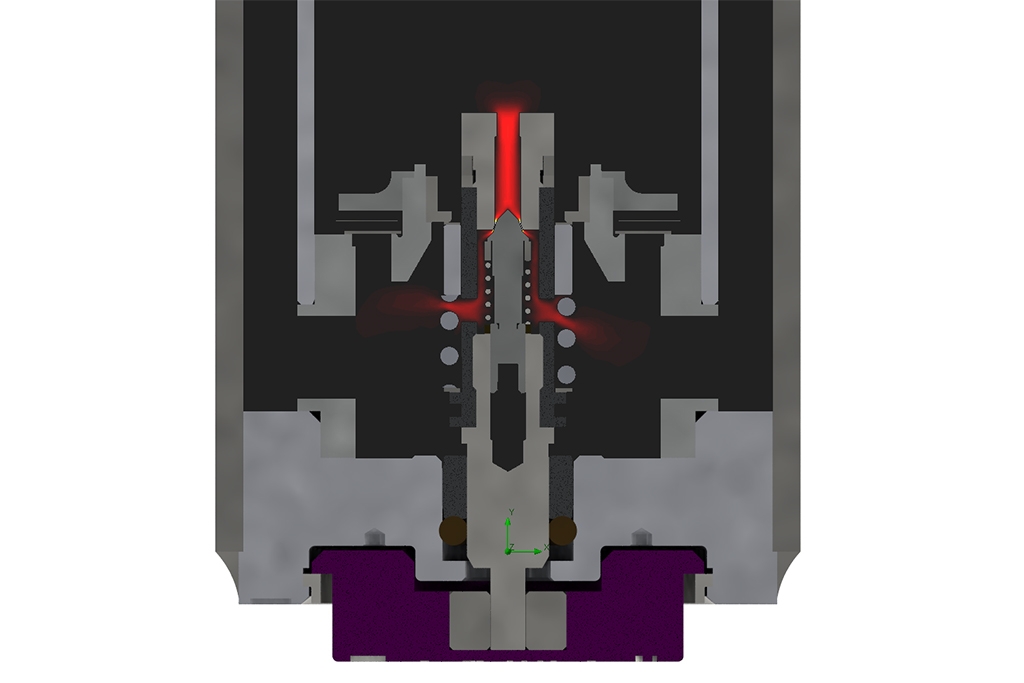

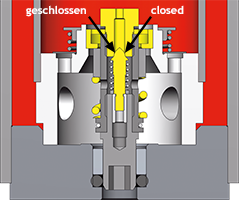

Oil flow during low compression setting

Figure 1:

Spring preloaded needle valve in the compression valve assembly in low compression state before stroke begins

Figure 2:

Position of the needle valve with increasing piston rod velocity

During slower piston rod velocities (black arrows), oil is flowing over the needle valve

The high speed compression damping (white arrows) is generated by the spring preloaded sleeve. The opened bypass valve produces a digressive characteristic compression damping graph in low speed ranges

The result:

The low speed damping of this technology enables a consistent high speed compression damping. The body support of the vehicle during the high speed damping range is not influenced with an opened or closed valve.

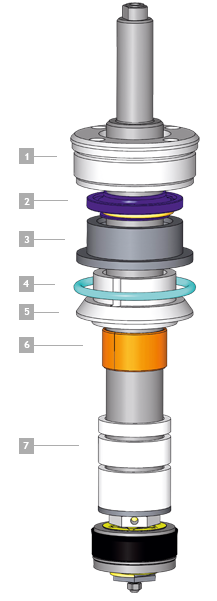

KW Piston Rod Guide and Sealing Package

Our modular sealing system exceeds OEM quality standards. It can be easily opened and allows maintenance of the valve technology or rod and piston.

- High tensile aluminum top sealing cap

- Self-lubricated special NBR seal package

- Clamp sleeve

- Temperature-resistant viton O-rings

- Guide bushing with bleed hole

- Special DU Metal-Polymer anti-friction plain bearings

- Polyamide rebound spacers

RIDE HEIGHT ADJUSTABLE

Configure the Ride Height to your needs

KW coilover suspensions, KW height adjustable springs, and KW DLC Air Suspensions allow the suspension to be lowered within the vehicle's technical limitations. For example, our Street Comfort products allow for a customized ride height setting with mild suspension lowering from 10 - 50 mm, while the Street Performance products allow the maximum technically possible suspension lowering range from 45 - 85 mm, depending on the vehicle. This means that the suspension can be lowered to suit the personal needs of the user and, depending on the product category, a setting ranging from Comfort to Performance can be chosen.

REBOUND ADJUSTABLE TECHNOLOGY

Adjustable Rebound Valve with KW TVR-A (Twin-Valve Rebound Adjustable) Technology.

The rebound stage damping is precisely tuned to the respective vehicle at our in-house drive dynamics test facility, delivered in the middle of the range out of the box. Individual customization can be achieved in 16 precise clicks, allowing you to choose between more comfort or more body control. The two-stage patented TVR-A technology allows the oil to flow through an adjustable, conical low-speed valve during slow piston speeds, while during higher piston speeds the main rebound stage valve opens to handle the flow of large volumes of oil. This provides major improvements in ride comfort without influencing the high-speed.

COMPRESSION ADJUSTABLE TECHNOLOGY (LOW-SPEED)

Adjustable Compression Valve with KW TVC-A (Twin-Valve Compression Adjustable) Technology.

The patented compression valve with TVC-A technology features two separate spring pre-tensioned valves for small and large volume flow. The compression is tuned to the respective vehicle type on our 7-post rig and is delivered in the middle of the range out of the box. With 12 precise clicks the adjustable compression valve can increase or decrease the cross-section in the low speed valve, providing more or less compression damping. In the event of sudden high piston speeds, the low speed spring pre-tensioned needle valve opens to its maximum volume along with the spring pre-tensioned main valve to maximize the volume of oil flow preventing unwanted progressive surges in the high-speed range with its blow-off feature. This makes it possible to support the vehicle body better while still offering more comfort than the conventional valve technology during high wheel travel acceleration. The compression stage damper setting is always supplied in combination with a separate rebound setting, only a truly independent 2-way damper setting allows for true performance optimization.

COMPRESSION ADJUSTABLE TECHNOLOGY (LOW-SPEED & HIGH-SPEED)

Adjustable Compression Valve with KW TVCLH-A (Twin-Valve Compression Low High - Adjustable) Technology.

The compression valve with KW TVCLH-A technology is high-end motor sports technology for the most demanding street and track performance customers. Two separate valves and a two-way adjustable compression valve allow separate compression damping changes in the low and high-speed range. The adjustments are made via two adjustment dials with click increments that feature 16 settings (with 15 clicks) for high-speed and 7 settings (with 6 clicks) of low-speed adjustability. During tuning at the KW driving dynamics test facility, the groundbreaking Variant 4 coilover suspension is tuned to the mid-range setting for the best road performance and provided with an additional recommended setting for occasional track day use. The 3-Way Clubsport coilover suspension is tuned to a mid-level factory setting especially for track day use, with additional range provided for adjusting to a varying degree of vehicle modifications and track conditions. Starting from the factory setting, the damping can be set firmer or softer for low and high-speed. The TVCLH-A technology has a blow-off feature with large cross-section. The resulting amount of low-speed forces create the best support for the vehicle body to keep the tires on the road in the case of wheel-induced high damper speeds (driving over curbs). The separate low and high-speed setting is always supplied with an additional rebound setting, to ensure an independent three-way damper setup.

COMPOSITE SPRING SEAT

Reinventing the way things are done

The KW coilover spring seat, also known as a spring perch, is constructed with a wear-resistant, friction-optimized polyamide composite material encompassing a stainless steel insert. In contrast to the anodized aluminum adjustable spring seats, the polyamide composite material prevents any possible oxidation while the stainless steel insert maximizes strength. In combination with the Inox-Line stainless steel coilover struts, this guarantees the long-term functionality of ride height adjustability.

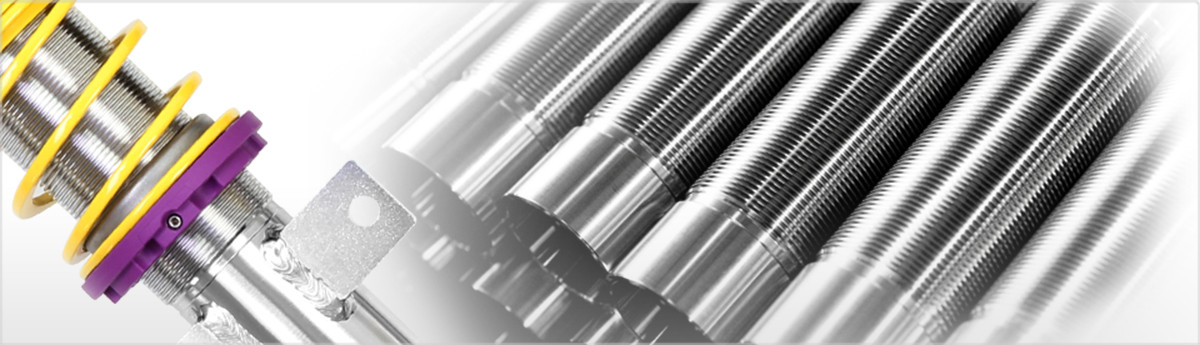

TRAPEZOIDAL THREAD

The Perfect Height-Adjustable Coilover

In comparison to common coilovers, KW uses a friction-optimized trapezoidal thread which is less sensitive to dirt and requires less force to adjust. Its large cross-section also provides a higher load-bearing capacity.

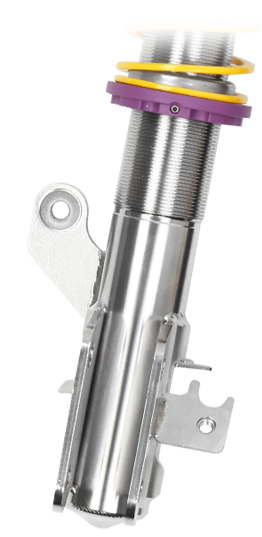

INOX-LINE

The Truly Permanent Corrosion Resistance

KW’s coilover suspension struts are manufactured from high-quality stainless steel that is rust-proof. In contrast to other solutions, Inox-Line coatings will not wear off while adjusting the suspension making KW coilover struts 100 percent corrosion resistant with an unlimited lifespan. Lowering the suspension using the trapezoidal thread in combination with the polyamide composite spring seat guarantees long term usability. Even after years the ride height adjustability is not affected.

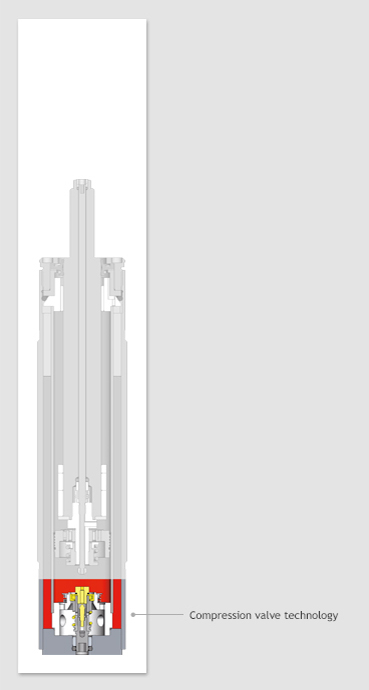

RESERVOIR

KW Twin-Tube Technology Knows No Limits

The KW reservoirs provide additional oil and cooling capacity for particularly high force systems. The reservoir, which is filled with low gas pressure, can be fitted anywhere and accommodate the adjustable compression valve to provide more working space inside the damper.

7-POST DRIVE DYNAMICS APPROVED

Testing to the Nth Degree

Used regularly by automobile manufacturers and international race teams, KW’s in-house 7-post drive dynamics test facility is utilized to optimally tune KW coilover suspensions according to the design and target group. The 7-post drive dynamics test facility is essential for fine tuning along with actual on-road evaluation on public roads and race tracks. In objective laboratory conditions, which can be reproduced at any time, we work everyday to give our customers the internationally-esteemed KW driving experience.

UNIBAL TOP MOUNT

More Track Performance & Adjustment Options

Depending on the vehicle application, the aluminum unibal top mounts feature a scaled camber adjustment and caster can be optionally adjusted. This means that the camber angle can be set, maximizing the tire contact patch when cornering, making handling even more direct. Please note: increased camber values are only recommended for track day use and may reduce tire lifespan when used on the road.

TECHNICAL COMPONENT REPORT

Certified Guidelines

The technical component report is always included in the package and outlines the guidelines for lowering the suspension of the respective vehicle. The technical component report ensures the vehicle remains useable when set within the guidelines provided in the installation instructions, allowing for an inspection and subsequent entry into the vehicle documents to be carried out without any problems. The technical component report also includes precise vehicle classification, requirements, and tips for safe fitting.These reports are required for road legal approval in many countries, check local laws.

KW TVR-A Technology

Twin Valve Rebound – Adjustable

The rebound stage damping is tuned to suit the respective vehicle at our in-house drive dynamics test facility and comes preset in the middle of the range out of the box. For custom settings the user has 16 precise click positions at their disposal, allowing them to choose between more comfort or more body control.

The two-step, patented TVR-A technology enables the small volume to flow through an adjustable, conical low-speed bypass in the case of slow damper speeds, while in the case of higher piston speeds, the main rebound stage valve opens for the large volume flows. This provides a big improvement in terms of ride comfort without influencing the high-speed range.

KW TVC-A Technology

Twin Valve Compression – Adjustable

The patented compression stage valve with TVC-A technology features two separate spring pre-tensioned valves for low and high volume flows.

The compression stage which is tuned to the particular vehicle type on our 7-post rig is supplied with a mid-range factory setting. With 12 precise clicks the adjustable compression stage valve can increase or decrease the cross section in the low-speed valve to achieve more or less compression stage damping. At the same time, in the case of sud-den high piston speeds, the spring pre-tensioned needle valve and the spring pre-tensioned main valve open to their maximum cross section, utilizing the blow-off feature to prevent undesired progressive power surges in the high-speed range. This allows for improved bracing of the vehicle body while simultaneously offering more comfort than with con-ventional valve technology in the case of high wheel acccelleration. The compression stage damper setting is always supplied in combination with a separate rebound stage setting, as only one independent 2-way damper setting allows for true performance optimization.

KW TVCLH-A Technology

Twin Valve Compression Low High speed – Adjustable

High-end motor sports technology for the most demanding street performance and track performance customers. The 3-way adjustable dampers utilize an independent and separately adjustable 2-way compression valve that enables compression damping changes for both the low and high-speed range. The compression adjustments are made via two adjustment controls on the housing using precise clicks. There are 16 settings for the high-speed range (with 15 clicks) and 7 settings for the low-speed range (with 6 clicks).

During tuning at the KW 7-post Driving Dynamic Test Center, the V4 coilover suspension is tuned so the preset recommended setting for best road performance is in the middle of the adjustment range with an additional recommended settings for the occasional track use. The 3-Way Clubsport coilover suspension is tuned with a preset recommended setting designed for track day use, with an additional recommended setting for the normal highway use. Starting from the factory setting, the damping can be set harder or softer in both the low and high speed ranges. The TVCLH-A technology has a blow-off feature with large cross-sections which allows for a substantial low-speed forces to provide optimum support of the vehicle body without unsettling the body in the case of sudden high damper stimulation induced by the wheels, like driving over apex curbing. The separate low and high-speed settings are always supplied with an additional rebound setting utilizing TVR-A technology for a truly independent 3-way damper setup.

HYDRAULIC ELEVATION

Lift It Up

With KW’s hydraulic lift system (HLS) the body can be raised for more ground clearance with the touch of a button, even while driving. With KW’s HLS, obstacles like speed bumps or steep parking garage ramps can be negotiated easily. The system can be used as a vehicle-specific retrofit solution for OEM dampers or as a complete suspension solution including the hydraulic equipment. The KW hydraulic lift system is available for the front axle or for both axles, depending on the application.

APP CONTROL

The KW iSuspension Innovation

With the KW iSuspension apps, customer-specific adjustments can be made simply and intuitively with your smartphone or tablet.

1.) The DDC ECU coilover suspension app allows a choice of three defined damper setups, Comfort, Sport, or Sport+ and also allows a complete individual customization of the adaptive dampers settings during operation.

2.) With the DLC app you can choose between a self-defined lowered suspension setting and the standard vehicle height. Precise adjustments can be made to the vehicle height when combined with our DLC air suspension modules.

Both apps are free to download in the Apple and Google Play stores and required the respective product and WLan module to operate.

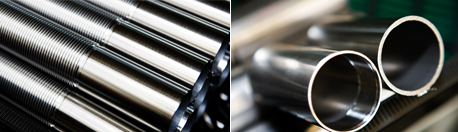

KW Stainless Steel Technology "Inox-Line"

Our KW stainless steel alloy "inox-line" coilovers are built to stand for many years of driving pleasure

We consistently set our KW coilover kits to the highest quality standards for perfectly matched components and materials. This not only benefits our renowned racing applications for international motorsport, but also your KW coilovers for the road.

All of our KW coilovers such as Variant 1, Variant 2, Variant 3, Variant 4, Street-Comfort, KW Clubsport 2-way and 3-way and the adaptive KW DDC coilovers are made of stainless steel. Whether it is the strut housing, the trapezoidal thread or the vehicle-specific brackets - we use only stainless steel. Our "inox-line" stainless steel alloy stands the test of time and elements for many years of driving pleasure, not just the life of the car.

- Highly corrosion resistant

- Unsurpassed quality

- No signs of wear at the adjustment mechanism after long term use

- Trapezoid thread in stainless steel ensures ease of ride height adjustment

- High load tolerance

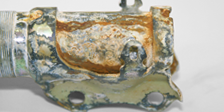

The Real Truth - The KW Salt Spray Test

How resistant are the KW "inox-line" coilovers to rust? We hear from our satisfied customers daily, but we still wanted to know more precisely so we worked together with the University of Applied Sciences in Esslingen DE. The chemists and engineers at the university tested the KW "inox-line" coilover struts made of stainless steel along with nine other coilover struts from six different manufacturers.

Competitors - Coilover suspensions, zinc-plated |

|

|---|---|

after 26 hours

|

|

after 145 hours

|

|

after 229 hours

|

|

KW coilover "inox-line" stainless steel |

|

|---|---|

after 26 hours

|

|

after 145 hours

|

|

after 229 hours

|

|

Participants/Products:

- KW coilover struts "inox-line" Variant 1, 2 and 3

- KW coilover struts galvanized in Variant 2

- 5 competitors with new, galvanized coilover struts

Evaluation:

- 2x very good KW "inox-line“ Variant 1 & Variant 3

- 1x good KW "inox-line“ Variant 2

- 2x moderately good competitors

- 1x moderate competitor

- 2x poor competitors

Final Test Result of the FH (University) Esslingen:

KW coilover struts in stainless steel technology "inox line" are clearly superior to galvanized versions in terms of corrosion resistance,

and ensure also after 480 hours a smooth operation.

Install Guide:

Warranty: