What is a Suspension Ball Joint? How do Ball Joints work?

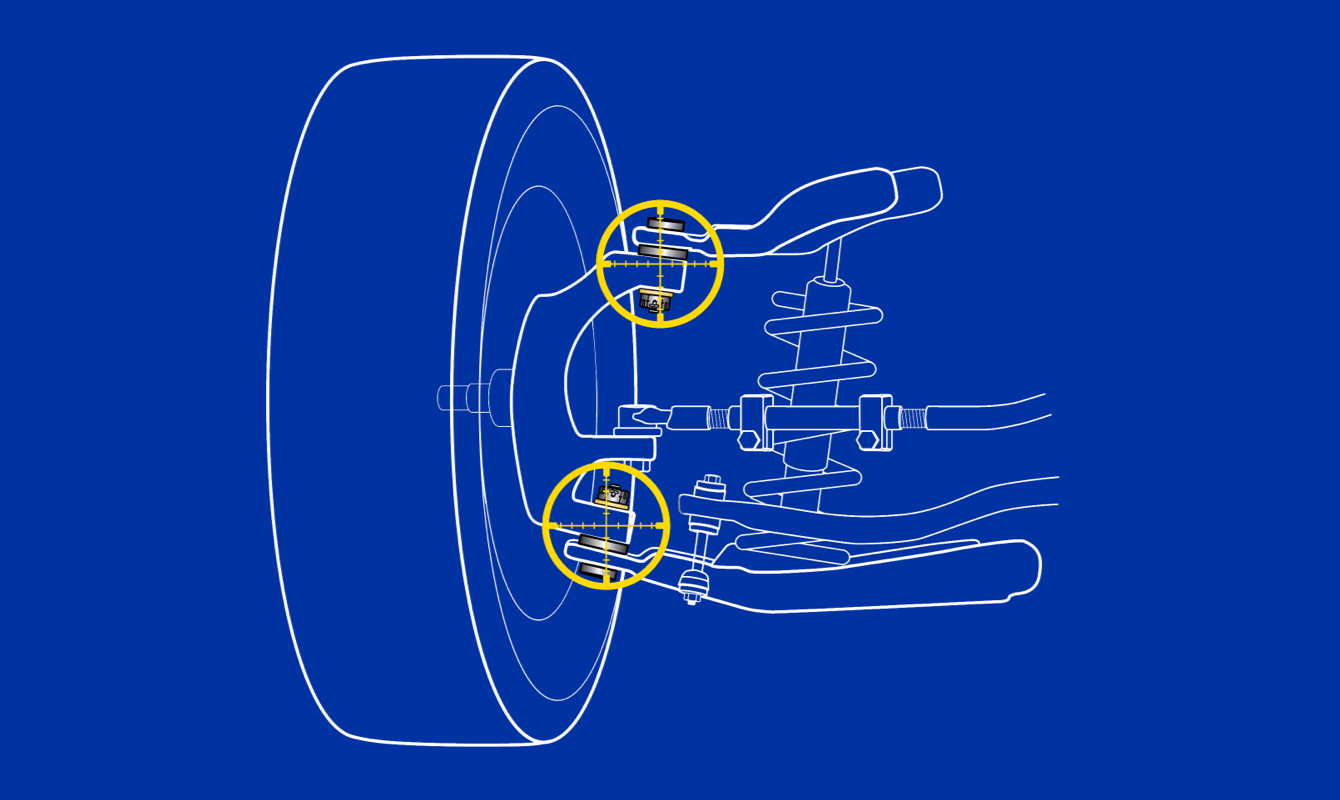

Ball joints and the independent front suspension

Ball joints are a component of the front suspension of a car. The front suspension is a complex assembly of links, joints, bushings and bearings that allow your front wheels to move up and down independently and turn left or right together. Ball joints allow suspension movement which maximizes the tire’s contact with the road providing optimum vehicle control and tire wear.

What do ball joints do?

Ball joints are the critical component of the front suspension that connect various links and allow them to move. Ball joints consist of a ball and socket similar to the hip joint of the human body. Ball joints of your front suspension provide pivoting movement between the steering knuckles and control arms to provide a safe, smooth ride and allow you to precisely control your vehicle.

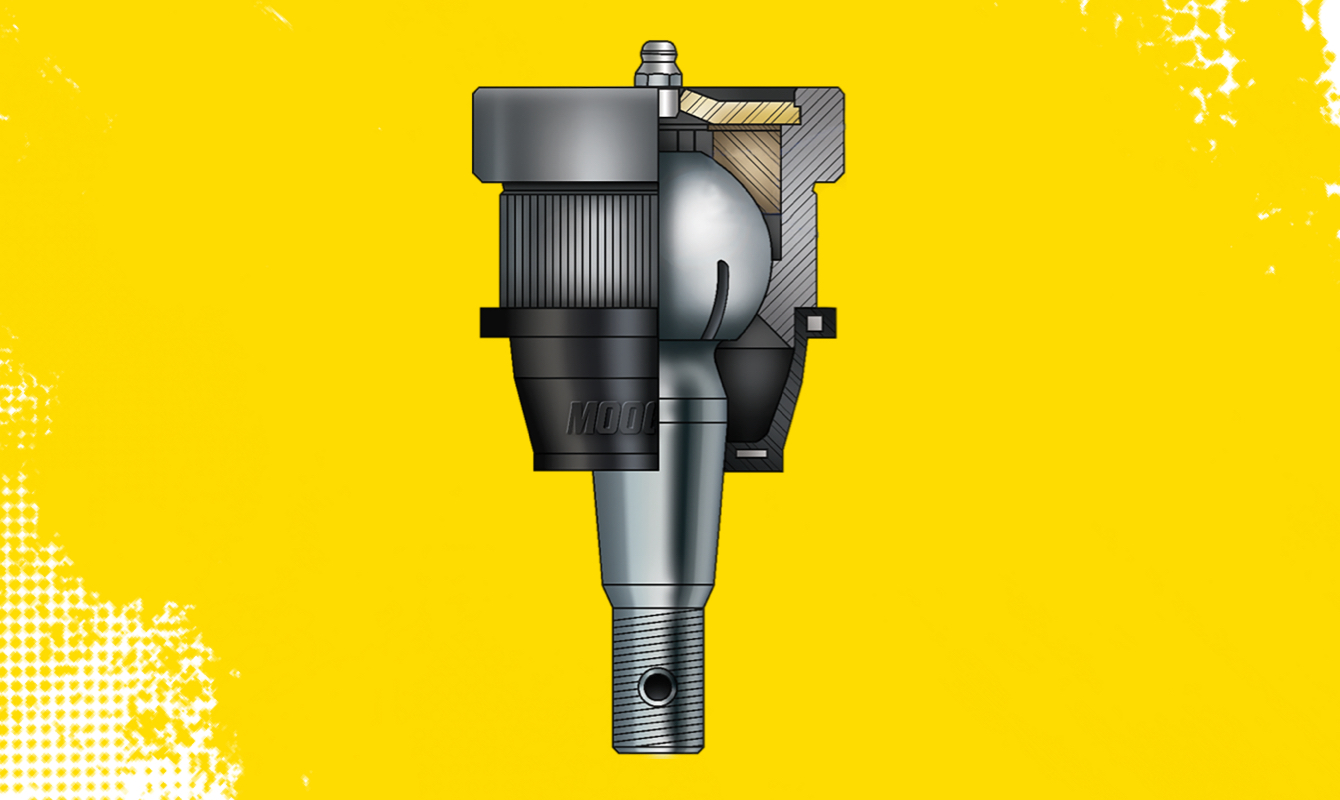

What are the parts of a typical ball joint?

Ball joints consist of a metal housing and a stud that can swing and rotate within the housing. Bearings inside the housing are placed between the ball stud and housing to help reduce wear and friction. The socket is filled with grease to provide lubrication, keep debris and water out of the socket, and maintain noise free operation. A rubber boot, located at the opening of the joint, keeps debris out and grease in. Lastly, the assembly is closed with a method such as the MOOG® pressed-in cover plate.

Many original equipment ball joints are designed as sealed units. If the protective boot fails, water and road debris will quickly cause wear and ball joint failure. Some aftermarket ball joints use an improved greaseable design that allows lubrication to flush out contaminants to extend the life of the joints.

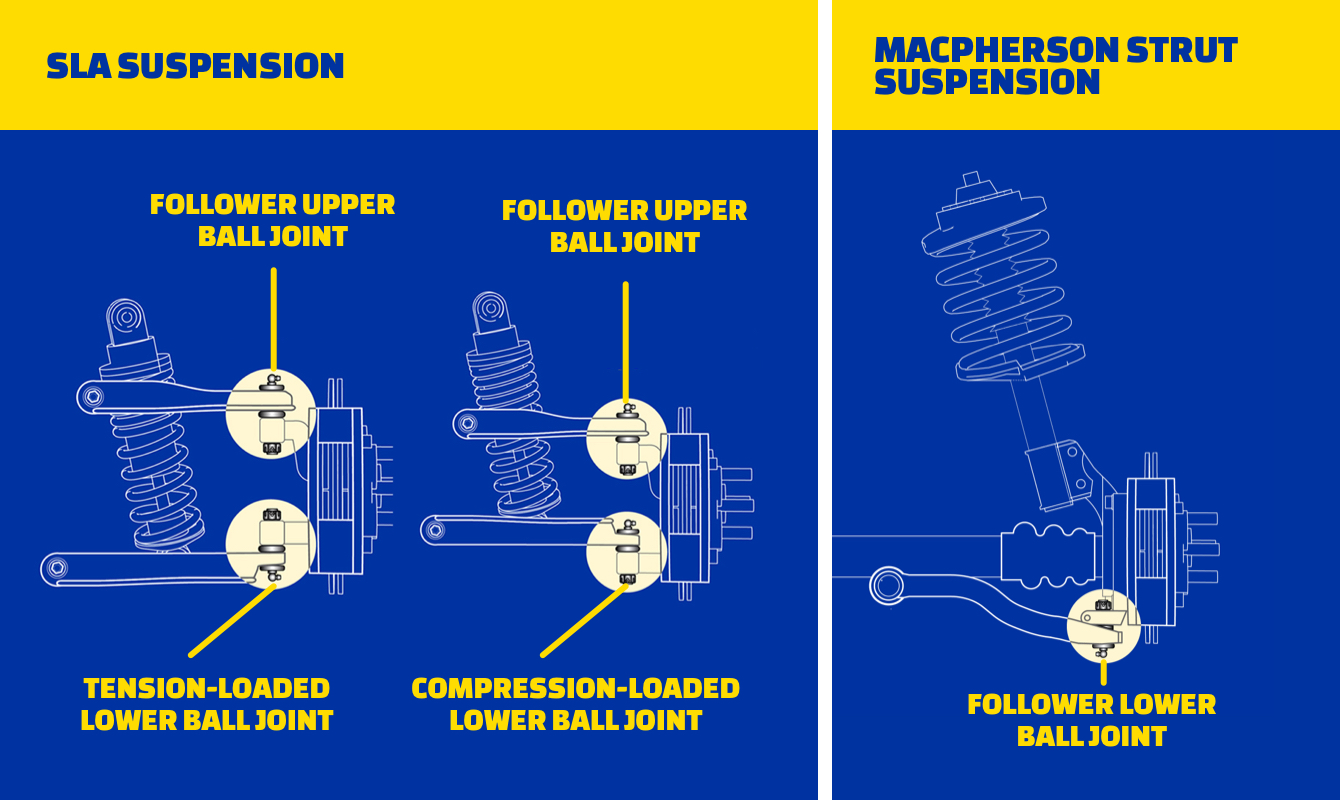

What are the different types of ball joints?

In your vehicle, you’ll find two different types of ball joints – upper ball joints and lower ball joints. While each of these ball joints serve different functions but both work together to keep steering reliable and responsive.

Upper Ball Joints

Designed to maintain alignment and absorb radial loads, such as turning forces, upper ball joints enable proper rotation of steering knuckle. Upper ball joints use a follower design.

Lower Ball Joints

Acting as a pivot point for the steering system, lower ball joints can either be load-carrying or follower types depending on the suspension design. Lower ball joints use a variety of designs: compression loaded, tension loaded and follower.

In a short long arm (SLA) suspension system, compression- and tension-loaded ball joints are load carrying ball joints that support the vehicle’s weight. These ball joints typically wear faster due to the additional stress on the socket. In MacPherson strut suspension systems, the lower ball joint is a follower design. Although they do not support the weight of the vehicle, they receive loading during cornering and braking.

Symptoms of loose ball joints

While ball joints may last 70,000 miles or more, they don’t last forever. Their actual lifespan will depend on your driving habits, road conditions and exposure to road splash and salt. As the ball and socket wear together, the normally close tolerance between them will increase and the ball joint will become loose over time.

Sound — Usually the first indication of worn or loose ball joints will be a faint, intermittent clunking noise that seems to be coming from a corner of your vehicle. The sound may be more pronounced when going over a bump or a dip or when going around a corner. While the sound may be faint at first, as time goes on and the wear continues, the sound will become louder and more frequent.

Steering — Worn ball joints can affect your vehicle’s steering, usually making the steering sloppy or stiff depending on how the ball joint is wearing. Feeling a vibration in the steering wheel while driving down a level, straight road, or your vehicle drifting to the right or left when going over bumps may also be signs of ball joint wear.

Front End Shimmy — Loose or worn suspension system components such as ball joints can contribute to front end shimmy. Worn ball joints become loose in the socket and cause excessive vibration when the vehicle is in motion. You may feel vibration through the seat, steering wheel or brake pedal.

Tires — Uneven tire wear may be a sign that your ball joints are wearing out. Specifically, if the inner or outer edges of your front tires are wearing out faster than the rest of the tread, there is a good chance that the cause is worn ball joints. However, if both edges are wearing out faster than the middle, the problem is not ball joints, but under-inflation of your tires.

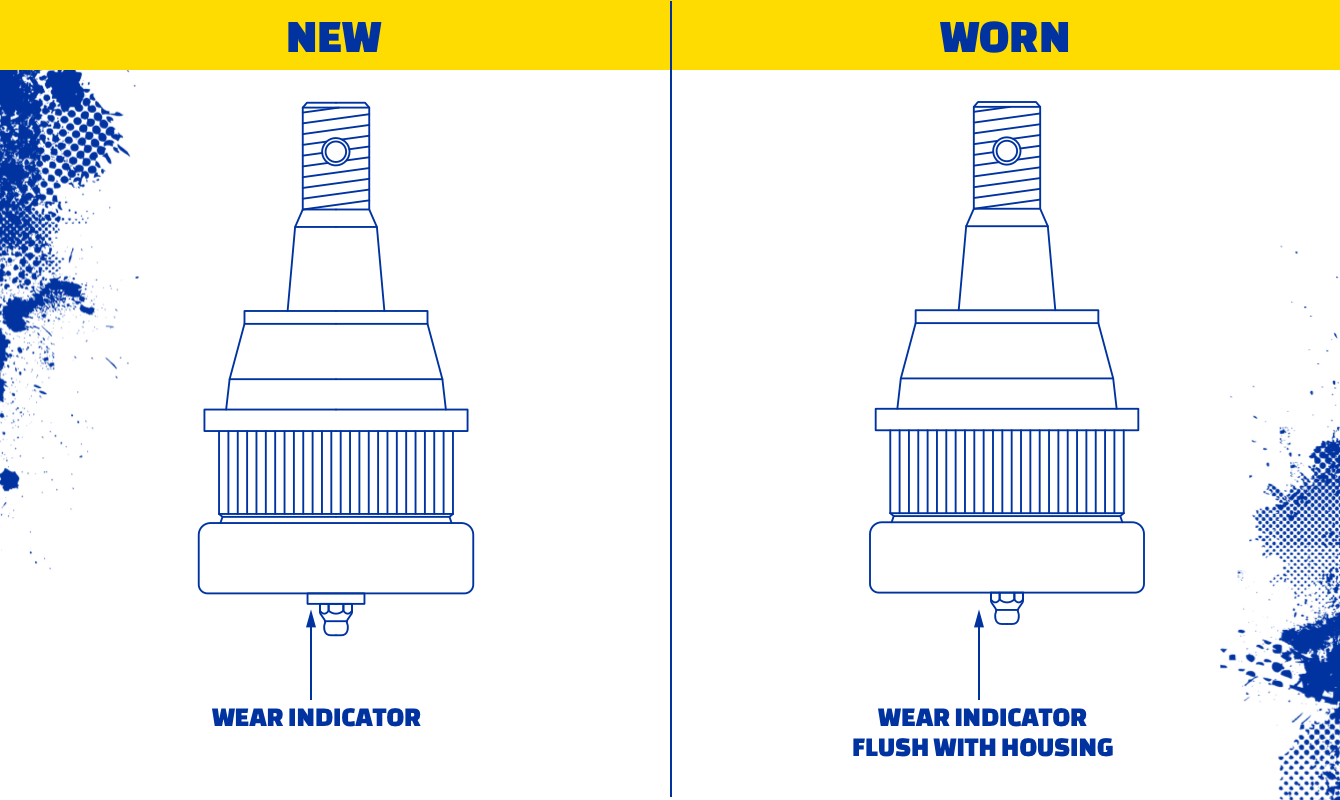

Ball Joint Wear Indicators

-1681159484507.jpg)

Ball joints for some older applications have a built-in wear indicator which makes identifying a worn ball joint easy. Wear indicators aren't common on newer applications because the ball joints are loaded in a different direction which makes them incompatible with wear indicators. If your vehicle’s ball joint doesn't have a wear indicator, you'll have to use a different technique to inspect the ball joint for looseness.

Wear indicators include a movable grease fitting. When a collar of the grease fitting is flush with or below the bottom of the ball joint housing, the ball joint is worn and should be replaced.

Other types have a wear indicator pin protruding through a hole in the bottom of the ball joint. As long as the pin is visible, the ball joint is OK. When it becomes flush with the housing or is not visible, then the ball joint should be replaced.

What are the risks of driving with a bad ball joint?

A worn ball joint is not a problem that should be ignored. If the wear becomes severe, the stud may separate from the housing resulting in immediate loss of control of your vehicle. Should you suspect worn ball joints, you should have your vehicle checked by a professional technician who has experience with diagnosing suspension problems.

How Do Ball Joints Work?

Ball joints are components located on the front suspension system of a vehicle. They help form a connection between control arms and steering knuckles. This provides smooth movement within the suspension.

Ball joints allow the steering knuckles to move in different directions while ensuring they remain attached to the vehicle. This motion allows the wheels to move up and down and side to side as needed.

A ball joint features a metal housing, a stud that can rotate within the housing and a socket enclosed in a lubricated casing. The ball stud is constantly moving when you’re on the road.

Upper and Lower Ball Joints

You can have upper or lower ball joints, depending on the type of vehicle and suspension. The difference is usually that upper ball joints are nonload-bearing (also known as “followers”), while lower ball joints are typically load-bearing.

When to Replace Ball Joints

Given the role they play in the suspension system, ball joints are going to experience daily wear and tear. At some point, they will need to be replaced.

The constant movement of the ball stud can cause it to become loose and move around inside the socket. As a ball joint wears out, more space develops between the stud and the socket, which can cause issues. Your safety could be at risk if ball joints become too worn out — in severe cases, the stud can pull out of the socket and cause a wheel to become partially disconnected from the vehicle.

Manufacturers often give specifications for the acceptable amount of space between the stud and the socket, which is good to familiarize yourself with. You can also watch for symptoms of worn ball joints, which include:

- Excessive vibration: Rattling and shaking that you can feel in the suspension or through the steering wheel can be a sign of wear and tear on the ball joints.

- Rattling or clunking noises: Ball joints that have become loose in their sockets have the potential to make all kinds of noises, including knocking, clunking or banging when going over bumps or turning.

- Irregular tire wear: Bad ball joints have the potential to cause uneven wear on the inside or outside of the tires.

- Car pulling to one side: A vehicle drifting to one side of the road could be a case of bad alignment, but it could also be a symptom of worn-out ball joints.

Leave a comment