With so many aftermarket intakes available, the natural question arises:

“So what’s so special about the Eventuri Intakes?”

There are two main elements in explaining the answer to what sets us apart from the rest:

- The Patented Eventuri filter housing design

- Our Bespoke Filters

- Our emphasis on creating a “Complete Solution”

The Patented Eventuri Filter Housing

Even at first glance the Eventuri intake looks very different to many other aftermarket intakes. Unlike the majority of intakes, which use the same cone filter/tube/heat shield configuration, the Eventuri design is fundamentally different and has been Patented.

AFTERMARKET INTAKE SYSTEMS

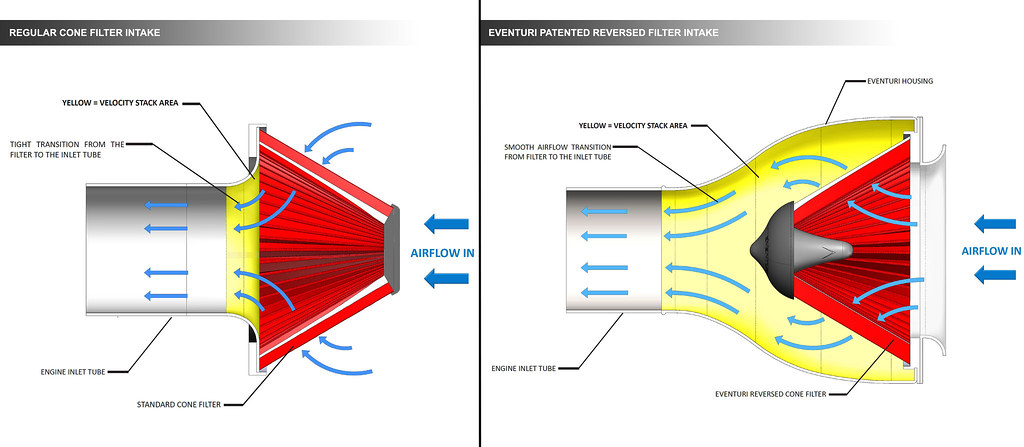

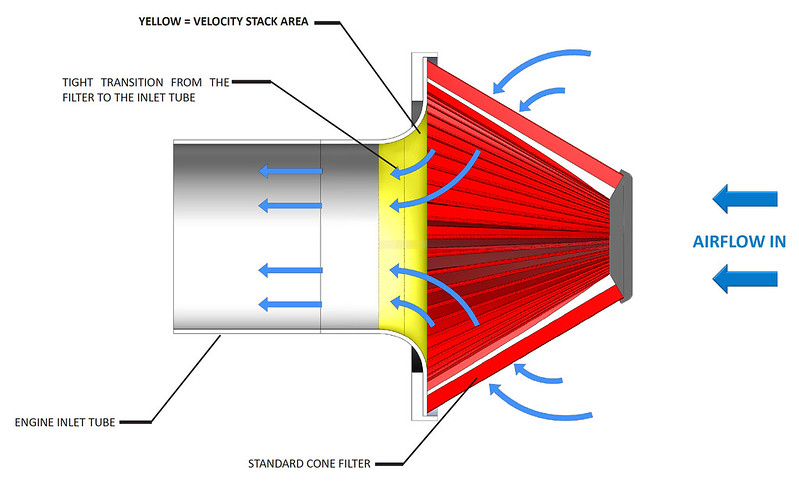

Most aftermarket intakes use a cone filter mated to an inlet tube with some type of heat shielding. In this configuration airflow must negotiate a path from the large diameter at the base of the filter through to the smaller diameter of the inlet tube in a relatively short distance. There is usually a velocity stack at the base of the filter to help with the transition, however the stack is usually small. This sudden transition in geometry is detrimental for flow. The result is a loss of throttle response and performance gains are usually limited over the OEM intake system. The diagram below shows a typical aftermarket intake using a cone filter secured to an engine inlet tube. The filter uses a standard velocity stack, which has been highlighted in yellow.

THE EVENTURI INTAKE SYSTEM

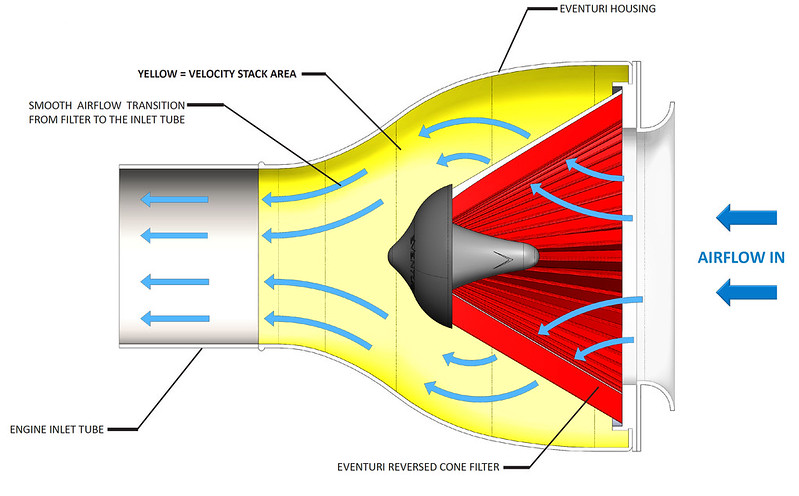

The Eventuri is a new type of intake design, which has been granted a patent. We use a cone filter – but here it is inverted and decoupled from the inlet tube. By removing the direct connection between the filter and the inlet tube, the filter is no longer dictating the shape of the airflow. This is now being done by the carbon housing, which is designed to smoothly guide the air into the inlet tube without a sudden change in geometry. This means that we keep laminar conditions throughout the intake, which is a lot more efficient. Furthermore, the funnel-shaped housing invokes the Venturi effect where the smooth reduction in cross-sectional area along the length of the housing causes the airflow to increase in velocity. Essentially the entire housing acts as a large velocity stack. On the road this translates to more power with a smoother delivery as well as sharper throttle response since the airflow is not inhibited by abrupt geometry changes andso is more likely to remain laminar. The diagram below shows an Eventuri intake system using a reverse mounted filter inside an Eventuri housing. The large velocity stack area is highlighted in yellow.