What is the Break In Procedure for New Brake Pads with Drilled and Slotted Rotors

WHAT IS THE BREAK-IN PROCEDURE?

IMPORTANT: FOLLOW THE PROPER BREAK-IN PROCEDURE FOR NEW BRAKE PADS/ROTORS USING THE PAD BEDDING PROCEDURE AS FOLLOWS. PROPER PAD BEDDING CAN PREVENT PERFORMANCE ISSUES.

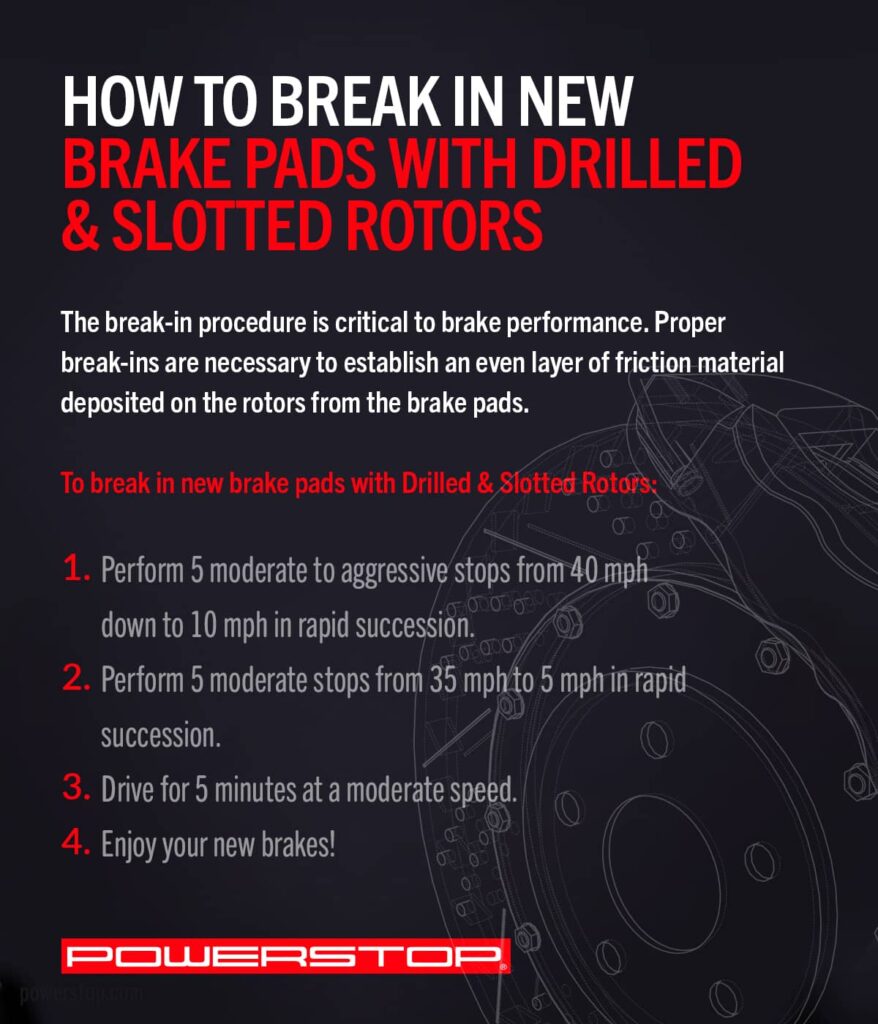

The break-in procedure is critical to brake performance. Proper break-ins are necessary to establish an even layer of friction material deposited on the rotors from the brake pads. It is very important that this initial layer of friction material is evenly distributed.

HOW TO BREAK IN NEW PADS WITH DRILLED & SLOTTED ROTORS

To break in new pads with Drilled & Slotted Rotors:

Perform 5 moderate to aggressive stops from 40 mph down to 10 mph in rapid succession without letting the brakes cool and do not come to a complete stop. If you’re forced to stop, either shift into neutral or give room in front so you can allow the vehicle to roll slightly while waiting for the light. The rotors will be very hot and holding down the brake pedal will allow the pad to create an imprint on the rotor. This is where the judder can originate from.

Then do 5 moderate stops from 35 mph to 5 mph in rapid succession without letting the brakes cool. You should expect to smell some resin as the brakes get hot.

After this is complete, drive around for as long as possible without excessively heating the brakes and without coming to a complete stop (Try for about 5 minutes at moderate speed).

This is the cooling stage. It allows the heated resin in the brake pads to cool and cure.

After the brakes have cooled to standard operating temperature, you may use the brakes normally.

DO YOU NEED TO BREAK IN BRAKE PADS AND ROTORS?

The break-in process for new brakes is called “bedding.” It involves the controlled heating up and cooling down of brakes to improve braking performance. During the bedding process, an even layer of brake pad material is transferred to the brake rotors. This can also help to prevent future brake fade by releasing gas from the pad material.

Breaking in new rotors is an important step that helps your new brakes perform well. This process ensures:

- Proper brake operation

- Smoother and quieter braking

- An accurate feel for how your new brakes operate

- Optimal performance

If the break-in process is skipped, the vehicle’s ability to slow down and stop is not optimal when the new brake pads are pressed against new rotors. A vehicle will stop much faster and smoother when a layer of brake pad material is already present on the rotor. The break-in procedure achieves this by applying an adequate base layer of pad material on the rotor to ensure optimal braking performance.

WHAT HAPPENS IF YOU DON’T BREAK IN NEW ROTORS?

Breaking in your rotors ensures that your braking system will perform to its full capacity. If you do not properly bed your rotors, your vehicle will not deliver optimal braking performance.

Braking systems that are not broken in will have random, uneven deposits of brake pad material on the rotors. When the brakes are engaged, this uneven layer could cause varying levels of pulsing in the pedal, shaking of the vehicle, and vibrations in the steering wheel.

To understand the effects of failing to bed new rotors, it is important to understand how friction affects the ability to brake. Brakes use friction to convert kinetic energy to thermal energy. This process involves two types of friction:

- Abrasive friction: This type of friction occurs when two surfaces rub against each other, namely when the brake pads are pressed against the rotor. With abrasive friction, the only force that stops the rotor from spinning is friction. Abrasive friction generates great amounts of heat. Heat can then soften the rotor, break down the particles of the brake pad, and cause the overall failure of the brakes and rotors.

- Adherent friction: This type of friction involves the thin layer of pad material on the surface of a rotor. When the brakes are applied, this thin layer of material bonds with the pad. As the pad moves across this surface, the bonds break and reform to create adherent friction. Brake pads that rely primarily on adherent friction can last longer because the pads do not grind down solely the rotor’s surface. They also tend to have less brake dust.

As abrasive friction cleans the surface of the rotor, adherent friction forms, breaks, and reforms pad material layers. These two types of friction work together to provide you with the friction needed to stop your vehicle. There are no pads available that rely solely on either abrasive friction or adherent friction (although some may rely on one mechanism more than the other).

Once the pads and rotors have been correctly broken in, a thin, even layer of pad material will be present on the surface of the rotor. This thin layer is the foundation upon which the brake system will stop your vehicle. When your brakes are properly broken in, abrasive friction will clean debris from the rotor and create a smooth surface for adherent friction to work. Adherent friction will break and reform the rotor and pad material’s bonds to leave a smooth layer of pad material to work with at the next rotation.

When rotors and pads have not been correctly bedded, the mechanisms of abrasive and adherent friction do not function ideally. This causes brake systems—especially at high temperatures—to create random and uneven deposits of brake pad material on the rotor’s surface. As mentioned above, this can cause brake pedal pulsing, steering wheel vibration, and vehicle vibration.

Leave a comment